Ever-expanding, always advancing TESCO EQUIPMENT, LLC will now offer CNC Metal Fabrication Shop in Coral Springs, Florida. In addition to our scissor lift services, we are doing Metal Fabrication, metal bending, and metal punch-formed workpieces. These services are monitored by our expert technicians from start to finish and overseen with your business needs in mind. Our experienced Welders and Fabrication Department are here to serve you.

Our current services offered are: Use FABRICATION in the e-mail subject line.

Our current services offered are:

APHS HYDRAULIC BREAK PRESS

The Baykal 300 tons of hydraulic adjustable pressure within a half-inch gauge capability, this break press can accept to a 12-foot length of metal and bend it to your desired need. The APH uses two actuated hydraulic cylinders in a downward force bending and folding the materials on the press.

The APH is CNC-controlled with a fully graphical user-friendly environment. The press is equipped with a high memory capacity for a multiple bend possibility if needed.

WELDING

Plasma welding on-premises. Experience the proficiency in our craftsmen’s handy work.

TRUMPF TRU PUNCH

The Trumpf TRU PUNCH is very versatile and a cost-effective way to process your fabrication needs.

TRUMPF CNC LASER

he Trumpf CNC LASER is a high-performance metal fabrication laser machine. This automated precision machine can cut 60″ wide by 120" long metal sheets. There is a tolerance of 5/8th and under for Mild Steel medium and 1/4″ and below for Aluminum medium sheets.

Laser Cutting

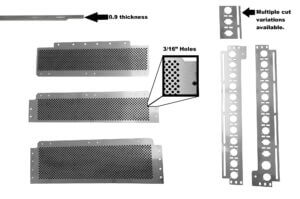

This particular job specification called for 0.9″ of an inch thick 304 Stainless Steel to be machined. The parts all had unique designs and quantities. The plates with flanges had holes the diameter of 3/16″ of an inch size in the center with various attachment points.

The elongated pieces shown above had holes as small as 1/8″ of an inch with other varied cuts all programmed on the Laser cutting machine.